Technical parameters:

1, features: single pipe independent control system.

2, optical system: F550 parallel light tube, focal length 550, aperture 55mm (optical error 10 meters ± 0.3mm);

3. Control system: self-developed digital LED light source adjustment;

4, display system: independently developed high-power lens, HIGH-DEFINITION CCD video acquisition single screen display;

5. Debugging method: manual debugging;

6, input voltage: AC220V/50HZ, maximum power 100W;

7, the requirements of the environment: workshop clean and tidy, above 1000 workshop, the station area to do a good job of protection, prohibit non-staff walking to touch the light tube.

One, foreword

Abstract: Parallel light tube is the most basic calibration instrument. In order to facilitate the installation and calibration of optical and laser instruments, the basic principle and structure of parallel optical tubes are introduced. It is mainly composed of objective lens, differentiation plate, ground glass, light source and mirror tube. The partition plate determines the different uses of the parallel light tube.According to the requirements of production practice, the surface design of the parallel light tube can provide a limited distance in the indoor target. It can be used for calibration of instruments and measurement of characteristic constants of optical systems.

Introduction: According to the principle of geometric optics, objects that are infinitely near will be imaged on the focal plane after passing through the lens. Instead, light from the focal plane of the lens will pass through the lens as a parallel beam of light. If an object is placed on the focal plane of a lens, it will appear at an infinite distance.

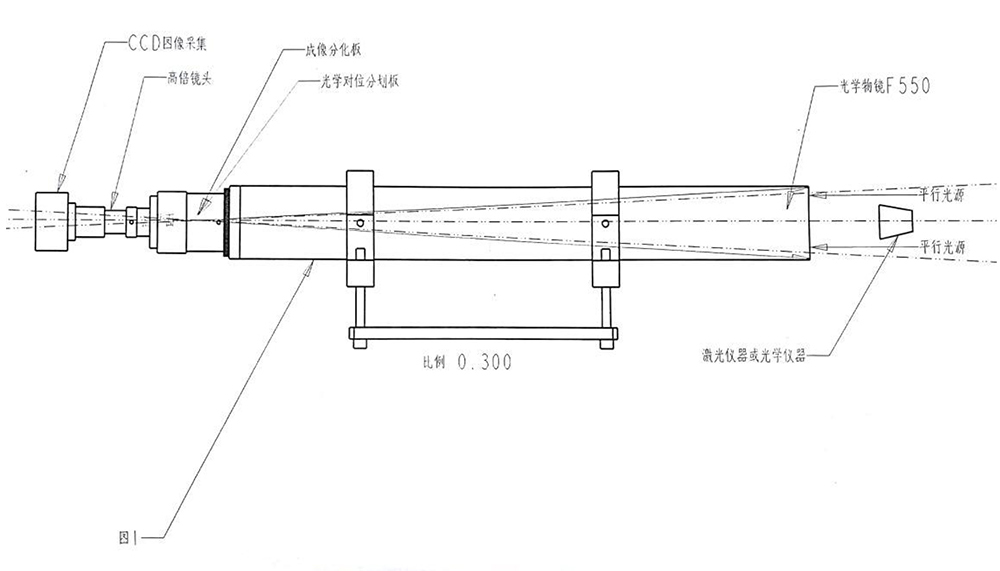

Structure principle of parallel light tube: See Figure 1

The structure principle diagram of the parallel light tube is composed of an objective lens and a demarcating plate placed on the focal level of the objective lens, a light source and ground glass arranged to make the demarcating plate evenly illuminated.

Since the splitter is located in the focal plane of the objective, when the light source illuminates the splitter, the light from each point on the splitter passes through the lens as a parallel beam of light. And because the partition board is engraved with a special cross scale value. These dividers with cross scale values will be imaged at infinity. In this way, to the observer, the splitter creates a target at a finite distance and at an infinite distance.

Conclusion: Parallel light tube is a basic optical tool used in the calibration process. It is very important to understand the basic principle and use of parallel light tube for the installation and calibration of optical instruments. Note: As a result of the parallel light tube as an optical detection instrument. And because the optical system of the parallel light tube is complex, the debugging is tedious, the steps are many, the variety is many. Therefore, it is necessary to choose products with different technical parameters and accuracy requirements according to different uses. At the same time, it is necessary to weigh weight, cost and other factors. It is necessary not to blindly pursue long focal length, large field of view, large caliber and high precision. Because of the price and technical parameters of the parallel light tube, the accuracy grade basically increases as an indicator. For example, the price of parallel optical tubes with the same focal length of 550MM will increase 4-5 times when the diameter is increased from 55MM to 100MM. A parallel optical tube with a focal length of 550MM, when the focal length is increased to 2M, the price will increase 1-2 orders of magnitude!

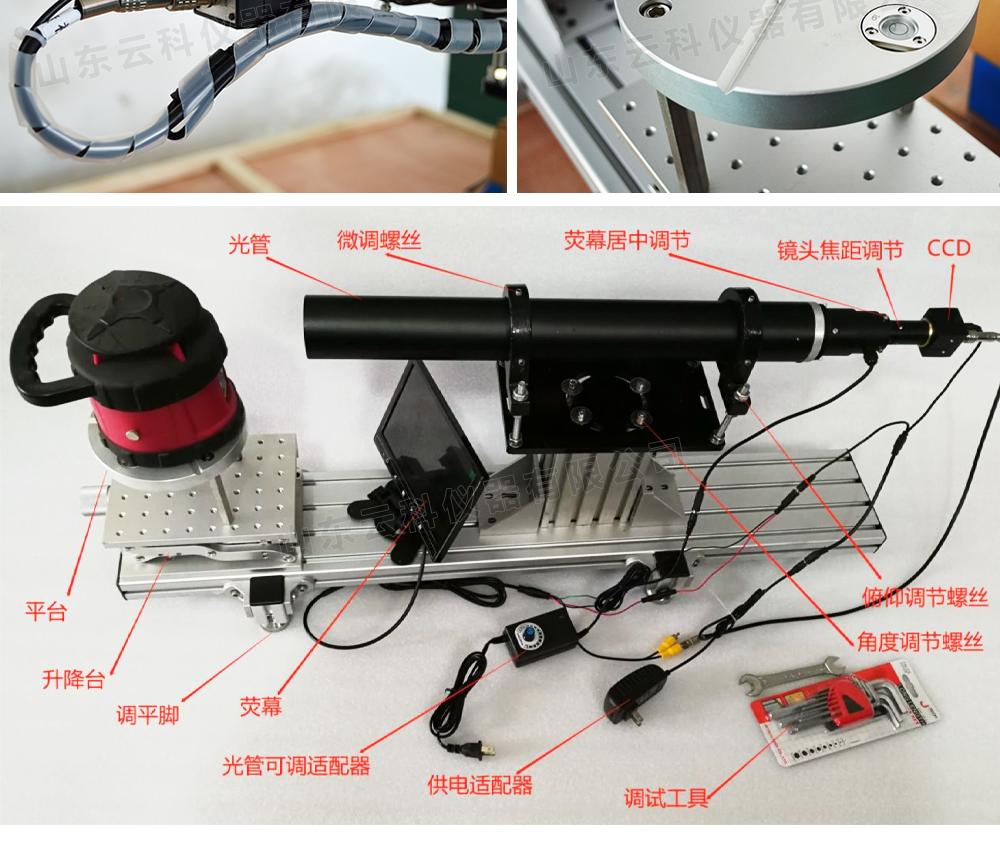

Two, photoelectric integrated parallel light tube structure

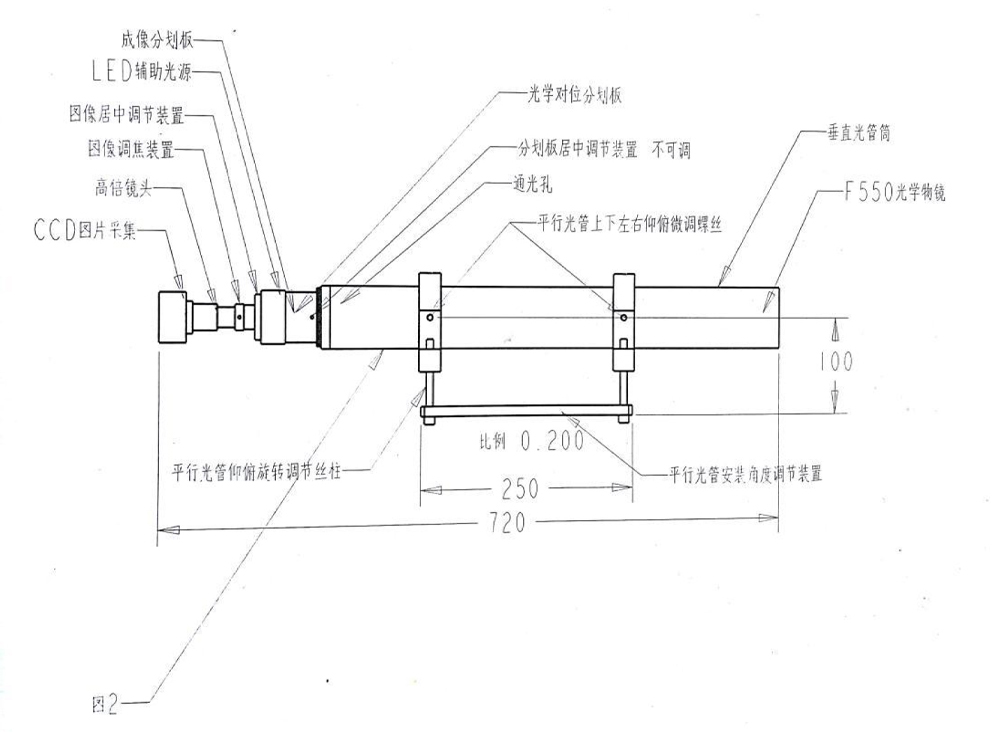

Basic structure of photoelectric integrated parallel light tube FIG. 2:

Since the splitter plate of the parallel light tube is completely in the focal plane of the objective lens and produces a parallel light beam, conversely, when a parallel light beam that is parallel to the objective lens hits the parallel light tube, it will be displayed in the cross center of the splitter plate of the infinite distance of the parallel light tube. Conversely, if the light not parallel to the objective hits the parallel light tube, it will not appear in the cross center of the splitter.

Using this characteristic of parallel light tube, we can use high power lens, HIGH definition CCD, video capture card. Record and display the characteristics of the light source on the partition board. It is convenient for us to adjust the parallelism, perpendicularity and straightness of the laser instrument.

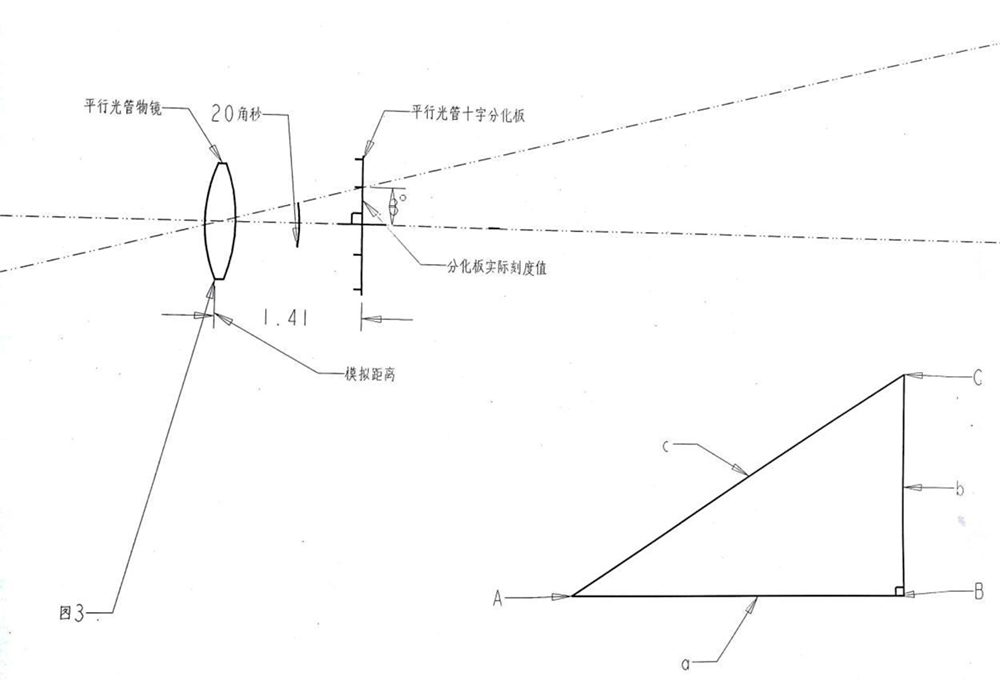

The differentiation board of the parallel light tube: the differentiation board of the photoelectric integrated parallel light tube is composed of two concentric and coaxial, two differentiation boards with different scale values. One is the differentiation plate used for correction, the scale value is small, the actual scale value is 0.05mm per grid, in the parallel light tube represents the Angle value of about 20 arcseconds (theodolite measured). One is to display the differentiation plate, the scale value is larger, the actual scale value is 0.1mm per grid, in the parallel light tube represents the Angle value of 40 arc seconds or so (theodolite measured).

Conversion of scale value of differentiation board of parallel light tube:

According to the principles of optical geometry, right triangle functions. As shown in figure 3;

校正刻度值换算:已知刻度值张角是 20 角秒(经纬仪测得)

我们设定张角 A=20 秒=0.0056 度

我们设定模拟距离 a=10 米=10000MM

分化板刻度值是 b

引用公式:

b=a*tanA

b=10000*tan0.0056

b=0.9744MM

所以:校正刻度值每格在 10 米处为 0.9744MM.

显示刻度值换算:已知刻度值张角是 40 角秒(经纬仪测得)

我们设定张角 A=秒=0.011 度

我们设定模拟距离 a=10 米=10000MM

分化板刻度值是 b

引用公式:

b=a*tanA

b=10000*tan0.011

b=1.914MM

所以:显示刻度值每格在 10 米处为 1.914MM.

包装和运输:

1,包装:木托或木箱

2,设备尺寸和重量:

净尺寸:长 1000MM*宽 200MM*高 370MM.

包装尺寸:长 1050MM*宽 250MM*高 430MM。

设备净重:30 公斤。

包装重量:35 公斤。

3,运输:普通陆运。

设备清单:

1,单管维修校正台主机 1 套(含支架)

2,控制主机(单路光源控制) 1 台

3,显示器(9 寸显示器,多功能支架) 1 副

4,F550 光电一体平行光管。 1 支

5,调试工具一套。 1 套

6,平行管原理说明书 1 份

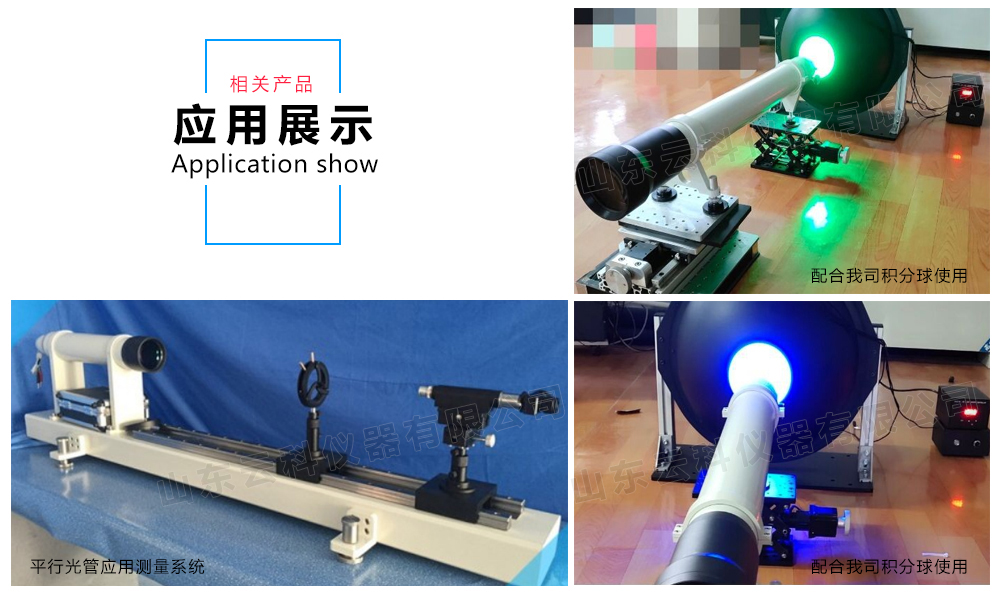

产品图片